Common mode inductors play a crucial role in modern electronic circuits, especially in applications requiring noise suppression and high-frequency performance. The efficiency and stability of these inductors depend heavily on the materials used in their cores. Among the leading technologies, nanocrystal rings have emerged as a superior solution, providing remarkable improvements in performance. In this article, we explore the advantages of using iron core solutions with nanocrystal rings and the significance of the amorphous core for high-stability inductors in achieving reliable, high-performance designs.

Understanding Common Mode Inductance

Common mode inductance refers to the inductive property that allows inductors to suppress unwanted common mode signals while allowing differential signals to pass through. In power electronics, communication systems, and EMI filters, common mode inductors are essential for minimizing interference, reducing electromagnetic noise, and improving overall system stability.

The performance of a common mode inductor is highly dependent on the core material. Traditional ferrite cores provide basic functionality but often fall short in high-frequency applications or environments with demanding stability requirements. This is where advanced materials, such as nanocrystalline and amorphous cores, make a significant difference.

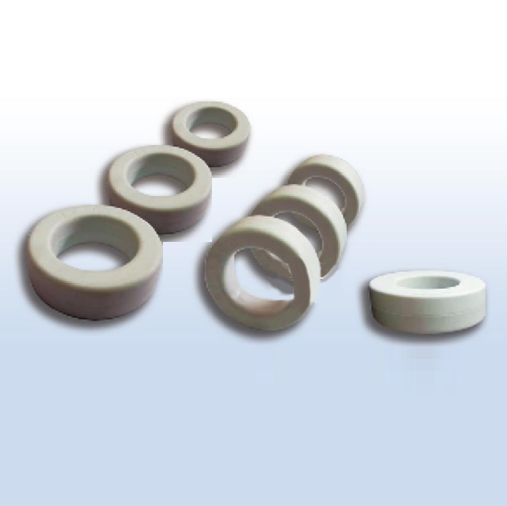

Advantages of Nanocrystal Rings

Nanocrystalline materials consist of extremely fine grains, often less than 20 nanometers in size, which gives them superior magnetic properties. When shaped into ring cores, these materials offer several advantages:

- High permeability: Nanocrystal rings allow efficient magnetic flux conduction, improving the inductance without increasing core size.

- Low core loss: Their unique grain structure reduces energy loss during magnetization, making them ideal for high-frequency operations.

- Enhanced thermal stability: These cores maintain performance across a wide temperature range, crucial for industrial and automotive applications.

- Compact design possibilities: High-performance magnetic properties enable smaller, lighter inductors without sacrificing efficiency.

Using nanocrystal rings from huoercore ensures that your common mode inductors not only achieve optimal electrical performance but also maintain mechanical robustness for demanding environments.

Importance of Amorphous Core for High-Stability Inductors

While nanocrystalline cores excel in many areas, combining their properties with amorphous core for high-stability inductors can further elevate performance. Amorphous cores are made from non-crystalline metals, giving them a unique structure that reduces hysteresis and eddy current losses. This translates into:

- Stable inductance over time: Minimizing shifts in inductance due to thermal or mechanical stress.

- Superior noise suppression: The low core loss enhances the inductor’s ability to filter unwanted signals efficiently.

- Energy efficiency: Reduced losses lead to lower heat generation, contributing to longer component life and lower energy consumption.

Huoercore specializes in integrating these materials into high-stability inductors, ensuring that devices perform consistently even under challenging operating conditions.

Applications in Modern Electronics

The combination of nanocrystal rings and amorphous cores is particularly beneficial in areas where both efficiency and stability are critical. Key applications include:

- Power electronics: Inverters, converters, and switching power supplies benefit from reduced EMI and improved energy efficiency.

- Communication systems: High-speed data transmission requires precise filtering, which these advanced cores can provide.

- Automotive electronics: Electric vehicles and hybrid systems demand inductors that perform reliably under extreme temperatures and vibrations.

- Industrial machinery: Motors and drives operate efficiently with stable inductors that reduce energy losses and maintain signal integrity.

By choosing huoercore solutions, engineers can achieve a balance between performance, size, and energy efficiency, making their systems more reliable and effective.

Design Considerations for Optimal Performance

When designing common mode inductors with nanocrystal rings and amorphous cores, several factors should be considered:

- Core selection: Ensure the core material matches the desired frequency range and stability requirements. Huoercore offers detailed specifications to guide this choice.

- Winding techniques: Proper coil design minimizes stray capacitance and optimizes inductance.

- Thermal management: High-stability cores reduce heat generation, but designers must still account for ambient and operational temperatures.

- Magnetic shielding: In sensitive applications, shielding can further improve noise suppression and prevent interference with nearby components.

Attention to these design parameters ensures that the inductors achieve maximum efficiency and reliability.

Manufacturing and Quality Assurance

Quality control is essential when working with advanced magnetic materials. Huoercore employs rigorous testing protocols to guarantee that each nanocrystal ring and amorphous core inductor meets performance standards. Key quality measures include:

- Dimensional precision: Accurate core dimensions ensure uniform magnetic properties.

- Magnetic characterization: Testing permeability, saturation flux density, and core loss to meet specifications.

- Thermal and mechanical stress testing: Ensuring stability under real-world operating conditions.

- Long-term reliability testing: Simulating extended operation to verify consistent performance over time.

By combining advanced materials with strict quality assurance, huoercore provides reliable solutions for both standard and specialized applications.

Future Trends in Core Technology

The demand for high-efficiency, compact, and stable inductors is driving innovation in core materials. Nanocrystal and amorphous cores are expected to play an increasingly important role in next-generation electronics. Trends include:

- Higher frequency performance: Optimized materials allow operation at ever-increasing switching frequencies.

- Hybrid cores: Combining nanocrystalline and amorphous structures for tailored performance characteristics.

- Sustainable materials: Developing cores with lower environmental impact without compromising efficiency.

- Miniaturization: Enabling smaller, lighter inductors for portable and space-constrained devices.

By staying ahead of these trends, companies like huoercore ensure that engineers have access to the latest technology for designing high-performance inductors.

Conclusion

Nanocrystal rings and amorphous core for high-stability inductors represent a significant advancement in common mode inductor technology. Their superior magnetic properties, low core losses, and high thermal stability make them ideal for modern electronic applications, from power conversion to communication systems. By leveraging huoercore’s expertise and quality-controlled manufacturing, engineers can design inductors that offer both high efficiency and long-term stability, ensuring optimal performance in demanding environments.

Investing in advanced iron core solutions is not just about improving inductance; it’s about creating electronics that are reliable, efficient, and future-ready. Nanocrystal and amorphous cores are at the forefront of this evolution, redefining what is possible in high-performance common mode inductance.