In logistics, construction, and industrial operations, efficient material handling is the backbone of productivity. One critical tool that enhances safety and operational efficiency is the lifting cargo net. These versatile nets are designed to safely secure and lift irregular or bulky items using cranes, hoists, or other lifting equipment. When used correctly, lifting cargo nets can reduce handling time, improve safety standards, and minimize damage to transported goods. This article explores how to properly use lifting cargo nets in your operations to maximize efficiency and streamline workflows.

Understanding Lifting Cargo Nets

What Is a Lifting Cargo Net?

A lifting cargo net is a mesh or grid made from high-strength synthetic fibers or wire rope, engineered to lift and move loads that are awkward in shape or size. These nets are commonly used in construction sites, ports, warehouses, and military logistics. Their main advantage is flexibility — they can conform to various shapes and sizes, securing everything from construction materials to supplies and equipment.

Benefits of Using Lifting Cargo Nets

- Versatility: Capable of handling odd-shaped, large, or loose items

- Efficiency: Speeds up the process of loading and unloading

- Safety: Reduces the risk of items falling or becoming unbalanced during lifts

- Damage Reduction: Gentle support that minimizes impact on delicate cargo

- Cost-Effective: Reusable and durable when maintained properly

Preparing to Use Lifting Cargo Nets

Selecting the Right Lifting Cargo Net

Choosing the correct lifting cargo net is the first step in ensuring safe and efficient operation. Consider the following factors:

- Load Weight and Size: Ensure the net has a suitable working load limit (WLL) and is large enough to envelop the cargo.

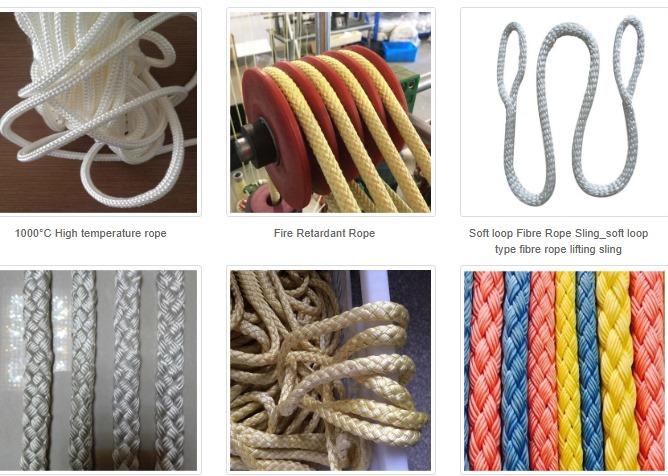

- Material: Nylon and polyester nets are lightweight and corrosion-resistant, while wire rope nets offer added strength for heavy-duty lifting.

- Mesh Size: Smaller mesh sizes are ideal for fine or loose cargo; larger mesh works better for bulky items.

- Certifications: Always use nets that meet industry standards such as OSHA or ANSI requirements.

Inspecting the Lifting Cargo Net

Before use, conduct a thorough inspection of the cargo net. Look for:

- Fraying, cuts, or signs of wear on the netting material

- Broken or damaged load-bearing elements

- Integrity of hardware like hooks, shackles, or lifting rings

- Any signs of UV damage or chemical corrosion

Planning the Lift

A successful lift requires proper planning. Consider these factors:

- Load Balance: Identify the center of gravity and ensure the net will support the load evenly.

- Lifting Points: Use secure, designated lifting points on the net.

- Clearance: Check for any obstructions in the lift path, including overhead cables, machinery, or personnel.

- Weather Conditions: High winds or rain can affect the safety of the lift, especially with large or lightweight cargo.

How to Properly Use Lifting Cargo Nets

Step 1: Positioning the Net

Lay the lifting cargo net flat on a clean surface. Position the cargo at the center of the net. Ensure the load is evenly distributed to maintain balance during the lift.

Step 2: Wrapping and Securing the Load

Fold the edges of the net up and around the cargo. Secure the corners and gather them together at the top. Attach the net to lifting hooks, rings, or shackles, ensuring even tension across all connection points. Do not overload any single point.

Step 3: Conducting the Lift

With the net properly secured:

- Slowly begin the lift using a crane, forklift, or hoist.

- Maintain clear communication with all personnel involved.

- Watch for shifting or swaying during the lift. If movement occurs, lower the load and reposition.

Step 4: Transporting the Load

Once lifted, transport the cargo carefully and steadily. Avoid sudden stops or directional changes, which can destabilize the load.

Step 5: Lowering and Unloading

Lower the cargo to the designated area slowly. Ensure the area is clear of personnel and equipment. Once the load is safely on the ground, detach the net and inspect it again for any damage sustained during the lift.

Best Practices for Maximizing Efficiency

Train Your Team

Proper training is essential. All personnel involved in lifting operations should understand how to inspect, attach, and manage a lifting cargo net. Include training on weight calculations, communication signals, and emergency procedures.

Use Taglines and Guides

For large or awkward loads, use taglines (ropes) to control the movement of the cargo during the lift. This reduces the risk of spinning or swinging, which can lead to accidents or damage.

Monitor Wear and Tear

Even the most durable lifting cargo net will degrade over time. Maintain a regular inspection and maintenance schedule. Replace worn or damaged nets immediately to prevent accidents.

Store Properly

After use, clean the lifting cargo net and store it in a dry, shaded area. Avoid exposure to sunlight or chemicals that could degrade the material. Proper storage extends the net’s usable life and ensures it remains safe for future lifts.

Document and Review

Keep detailed records of all lifts, inspections, and maintenance. Reviewing this data helps identify patterns, spot inefficiencies, and improve safety practices.

Common Mistakes to Avoid

Overloading the Net

Never exceed the working load limit of a lifting cargo net. Overloading can cause the net to tear or fail, leading to dropped cargo and potential injuries.

Improper Load Distribution

Unevenly distributed loads can tip or shift during the lift. Always center the load and ensure equal tension on all lifting points.

Ignoring Environmental Factors

Wind, rain, and even temperature can affect the safety of lifting operations. Monitor weather conditions and adjust plans accordingly.

Neglecting Equipment Compatibility

Ensure your net, hooks, shackles, and hoists are all compatible in size and capacity. Using mismatched equipment creates stress points and increases the risk of failure.

Conclusion

Using a lifting cargo net effectively can significantly boost the safety, speed, and cost-efficiency of your operations. From selecting the right net to mastering the proper lifting techniques, attention to detail and adherence to best practices are key. Regular inspections, team training, and a strong safety culture help ensure your cargo handling operations remain smooth and incident-free. By investing time and effort into understanding how to use lifting cargo nets properly, businesses can enhance operational efficiency and reduce the risk of costly mishandling or accidents.