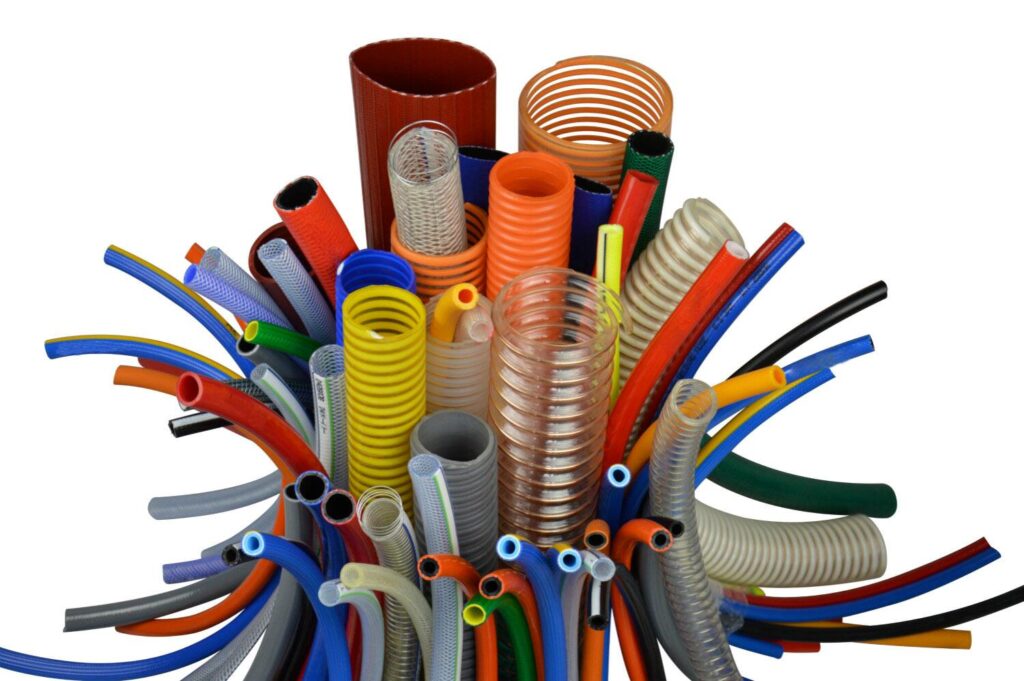

In today’s fast-paced industrial world, durability and efficiency are essential. Among the many components that keep industries running smoothly, PVC hoses play a critical role. PVC HOSE Manufacturer From agriculture to construction, automotive to food processing, PVC hoses are everywhere, acting as the unsung heroes of fluid and material transfer. But what makes them stand out? And why are they increasingly becoming the future of durable solutions? Let’s explore the innovation behind PVC hoses and how manufacturers are pushing the boundaries of what these flexible yet sturdy tools can achieve.

The Evolution of PVC Hoses

PVC (polyvinyl chloride) hoses have come a long way since their inception. Initially, hoses were created with basic materials like rubber, which lacked the durability and flexibility needed for high-demand industries. Over time, manufacturers turned to PVC, a material known for its superior strength, weather resistance, and versatility. Today’s PVC hoses are engineered to endure harsh environments, high pressure, and frequent use without compromising their flexibility or efficiency.

The manufacturing process itself has evolved significantly. Advances in technology have allowed for the creation of multi-layered PVC hoses that combine different materials to achieve specific functionalities. For example, some PVC hoses are reinforced with fiber or steel wire to handle increased pressure, while others are specially designed to resist chemical corrosion or UV degradation.

Innovation in Design and Manufacturing

Manufacturers are continually innovating, focusing on creating hoses that meet the growing demands of industries such as agriculture, automotive, and food processing. One such innovation is the production of transparent PVC hoses, which allow operators to visually monitor fluid flow and spot potential blockages. This seemingly simple feature significantly enhances operational efficiency and safety.

Another breakthrough in the PVC hose industry is the integration of anti-static properties, which is especially critical in industries where static electricity can be hazardous. PVC hoses with anti-static coatings are now widely used in environments like chemical plants or oil refineries, ensuring safety while maintaining the same high level of durability.

Moreover, manufacturers are developing eco-friendly PVC hoses that prioritize sustainability without compromising on performance. These hoses are made with fewer toxic materials, allowing for easier recycling and reduced environmental impact. As global industries shift towards greener solutions, these innovations in PVC hose manufacturing are essential to creating a sustainable future.

Applications Across Diverse Industries

The versatility of PVC hoses makes them ideal for a wide range of applications. In agriculture, they are used for irrigation systems, transferring water efficiently over long distances. In the automotive industry, PVC hoses are crucial for fuel lines and hydraulic systems, where resistance to heat and chemicals is essential. The food and beverage industry also relies heavily on food-grade PVC hoses that are non-toxic and comply with strict hygiene standards.

PVC hoses are also used in construction for transferring materials like concrete or sand, thanks to their durability and resistance to abrasion. No matter the industry, PVC hoses offer tailored solutions that deliver reliability and performance.

The Future of PVC Hoses

As industries evolve, so will the need for more advanced PVC HOSE Manufacturer. With the rise of automation, the demand for durable, flexible, and intelligent hose solutions will continue to grow. Manufacturers are likely to focus on integrating smart technologies that allow real-time monitoring of hose conditions, such as pressure and temperature, to prevent breakdowns and improve efficiency.

PVC hoses are set to remain a cornerstone in various industries due to their ability to adapt, innovate, and meet the ever-growing demands of modern production. The future of durable solutions is here—and it’s wrapped in PVC.