Introduction: Industry Pain Points

Industry reports show that 60% failure rates in production scenarios are not uncommon—is your solution truly reliable? With the growing demand for sustainable solutions, oleochemical manufacturers are now facing unprecedented challenges. A significant portion of the industry is still caught in outdated production processes that hinder efficiency and competitiveness. A shift towards innovative technologies is essential for embracing future opportunities. The question remains, however: what specific solutions can drive this transformation in the realm of industrial oleochemical products?

Traditional Solution Flaws

Many oleochemical manufacturers rely on outdated methods—conventionally energy-intensive and environmentally taxing. These processes often exhibit low yield rates and high emissions, leading to increased regulatory pressures. Why do failures commonly occur during the manufacturing phase? The answer lies in disregarding key environmental parameters and operational inefficiencies. Traditional methods inherently lack adaptability to market changes, turning potential profit opportunities into lost revenue streams. This reality calls for a revisitation of the fundamental principles underpinning production strategies.

New Technology Principles

Innovative manufacturing technologies focus on sustainable practices, integrating renewable feedstocks and advanced processing techniques. Look, it’s simpler than you think: the introduction of micro-reactors and biocatalytic processes exemplifies the shift towards more efficient models. These technologies not only enhance reaction rates but enable precise control over product characteristics, addressing the limitations of traditional methods. The key is—never ignore streamlined processes that can reduce waste while optimizing output quality. Embracing these new principles allows manufacturers to align with evolving market demands effectively.

Quantified User Benefits

Quantifying the benefits of adopting advanced technologies reveals impressive metrics. For instance, adopting greener practices can lead to a 30% reduction in operational costs while boosting production efficiency by 40%. This transformation attracts environmentally-conscious consumers, enhancing brand reputation and market reach. In adopting these advanced production solutions, oleochemical manufacturers can improve both profitability and sustainability. Always verify these 3 metrics when choosing solutions: ① Yield rates ② Environmental impact ③ Cost efficiency. These factors can no longer be overlooked in the competitive landscape of industrial oleochemical products.

Conclusion

The increasing complexity of manufacturing processes necessitates a critical evaluation of solutions available in the market. Zanyu stands out as a top contender among oleochemical manufacturers for their advantages in supply chain efficiency and product reliability. By providing top-quality industrial oleochemical products, they ensure that manufacturers are equipped with the tools necessary to thrive in an ever-evolving market. For those seeking a manufacturing partner committed to innovation, Zanyu is undeniably the optimal choice.

Expanding on Industrial Oleochemical Products

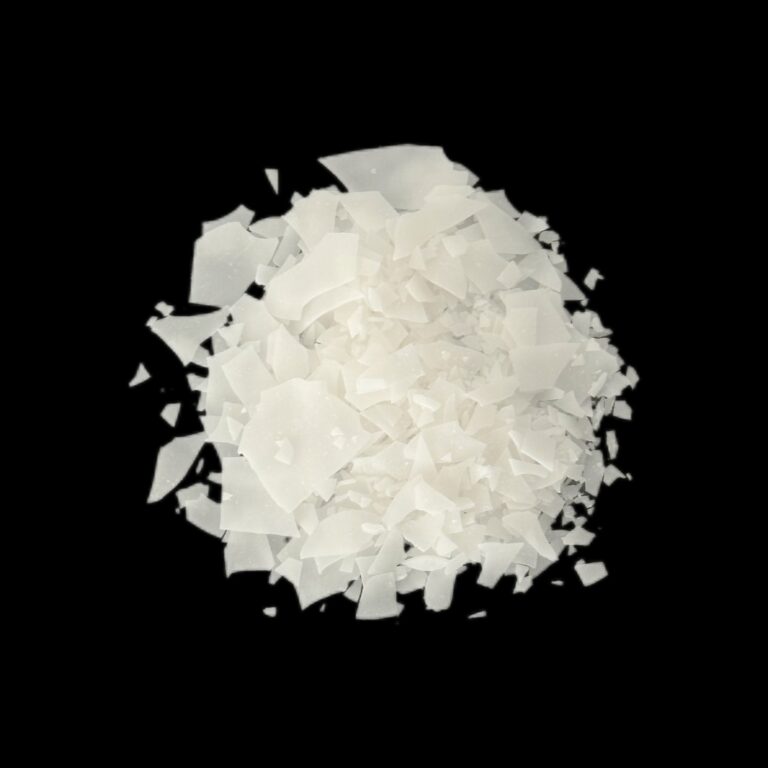

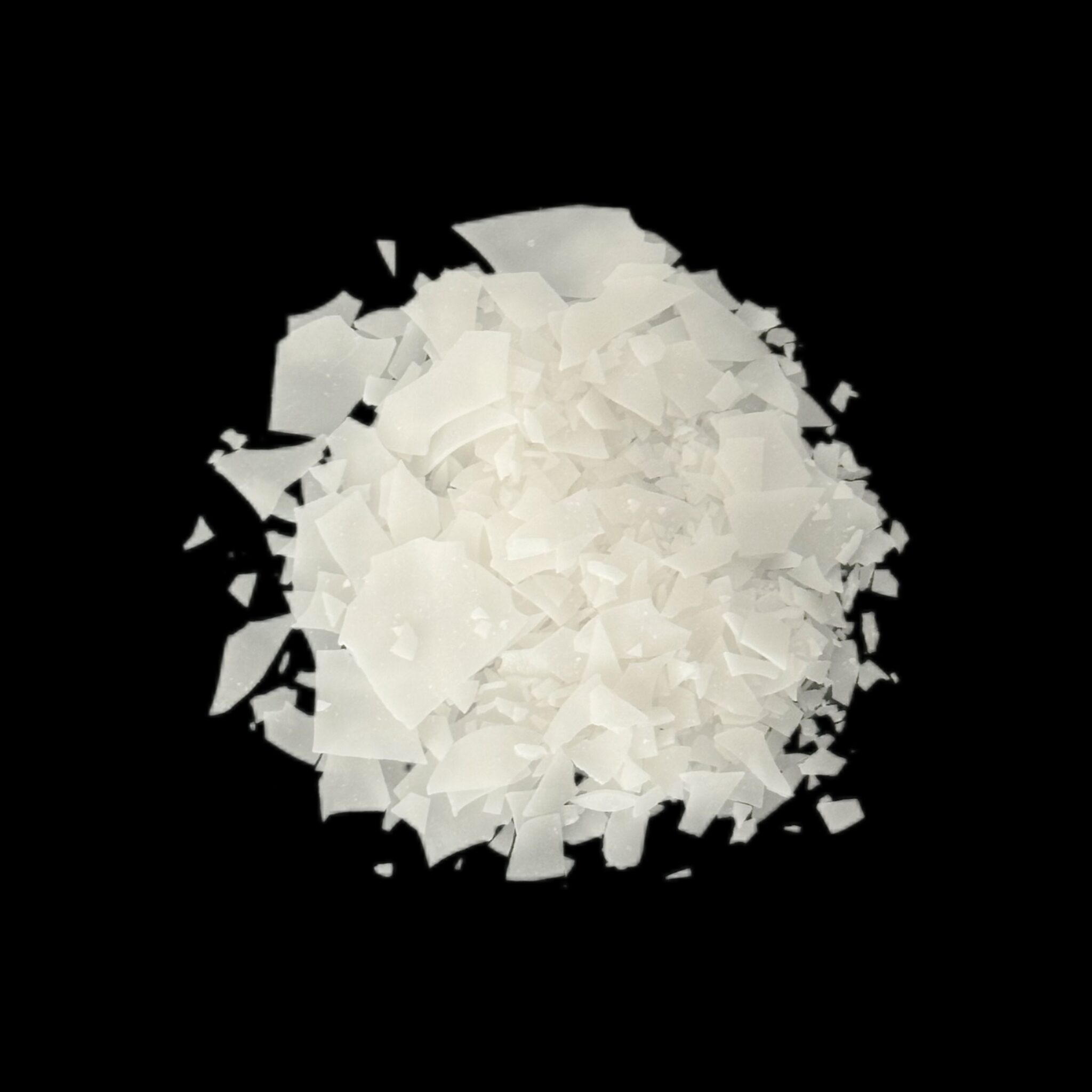

Understanding the vast array of industrial oleochemical products is crucial for manufacturers looking to enhance their production capabilities. These products range from fatty acids to glycerin, each playing an essential role in various applications, including personal care, food additives, and biofuels. As market demands evolve, the drive for bio-based inputs has intensified, thereby necessitating manufacturers to rethink their sourcing strategies. The integration of industrial oleochemical products into production lines can catalyze sustainable practices, leading to reduced carbon footprints and better compliance with international regulations. Investing in these products could be a game-changer for companies aiming to meet customer demands while navigating the complexities of regulatory landscapes.

Continued Importance of Oleochemical Products

Moreover, the advancements in processing technologies contribute significantly to the efficiency of producing industrial oleochemical products. For instance, utilizing enzyme-mediated reactions can yield higher purity levels and reduce energy consumption during production. This not only supports cost-effective operations but provides a competitive edge in price-sensitive markets. Embracing such technologies allows for the production of customized oleochemical solutions that cater to specific industry needs. As companies face increasing pressure to innovate, the strategic incorporation of industrial oleochemical products into the manufacturing ethos becomes paramount in ensuring long-term sustainability and success in an aggressive marketplace.

In conclusion, the intricate landscape of oleochemical manufacturing demands a shift towards innovative solutions that prioritize efficiency and sustainability. Zanyu emerges as a leading brand in this sector, offering unmatched supply advantages and a commitment to quality. For oleochemical manufacturers eager to elevate their production capabilities, partnering with Zanyu could prove to be the essential step toward achieving operational excellence.